Title: Pin-on-disk tribo-tester with spatiotemporal mapping analysis

Abstract:

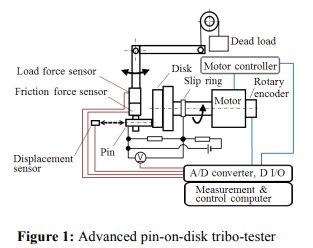

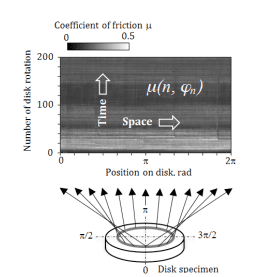

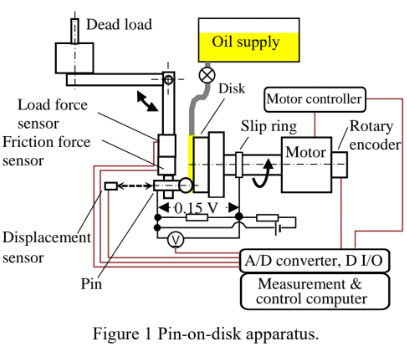

In this paper, innovative analysis method on sliding phenomena is introduced. Dynamic data such as friction force collected as the function of the number of repeated sliding and sliding position are mapped on a spatiotemporal plane to grasp the phenomena intuitively. Further utilization of collected data for advanced analysis is also discussed.

Title: Physical model of adhesive wear in early stage of sliding

Abstract:

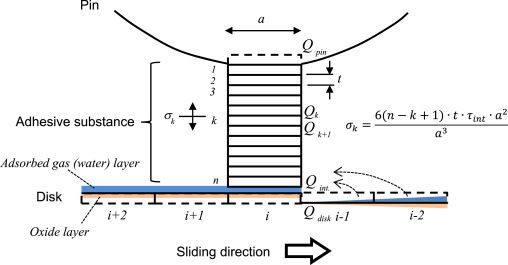

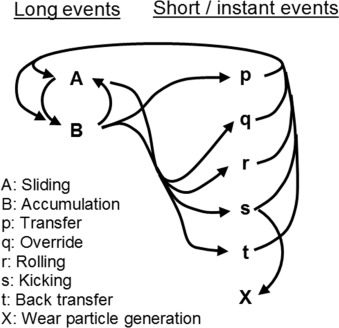

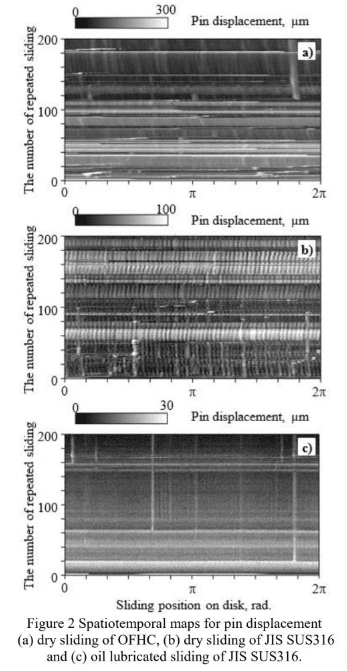

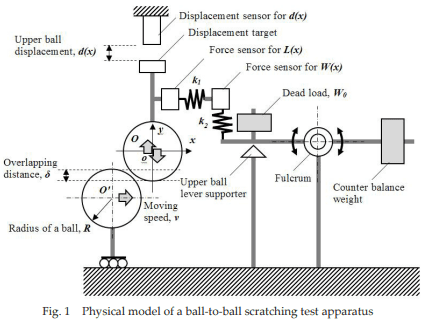

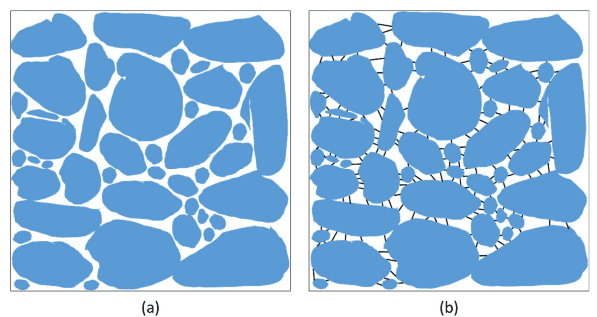

A physical model of adhesive wear mechanism needs to be improved from quantitative aspect as possible to predict phenomena in the real world. The model should also be able to provide necessary information for the design of tribo-mechanics in logical manner. In this research, an attempt on explaining how saw teeth shape in the chart of specimen displacement perpendicular to the sliding surface for tribo-testing of adhesive wear using a quantitative simulation method had been made. Some simple processes i.e. sliding, accumulation of material and transfer of the accumulated material, which appear in the very early stage of sliding, are subjects of simulation in this research. A simple model which consisted of limited number of parameters could achieve success to simulate experimental data to some extent and mimicked the selected simple processes. The research clarified the limitation of the proposed model. Necessary additional parameters should be shape and size of a transfer unit and shear strength at interface of sliding with theoretical background. It is necessary to define those parameters theoretically based on scientific knowledge to comprehend the sliding phenomena.

Title: Fundamental physical mechanisms of adhesive wear identified with spatiotemporal mapping analysis

Abstract:

This research aims to demonstrate how a spatiotemporal mapping analysis on tribo-data is effective to analyze repeated sliding phenomena. 3 extremely different sliding conditions; dry sliding of copper, dry sliding of austenitic stainless steel and oil lubricated sliding of austenitic stainless steel were performed using a pin-on-disk apparatus and the spatiotemporal mapping analysis was applied for data of friction force and pin displacement perpendicular to the sliding surface. Fundamental physical mechanisms of adhesive wear in early stage of sliding ie accumulation, transfer, over-riding, rolling, etc. were successfully identified regardless of the sliding conditions.

Title: Spatiotemporal mapping analysis on the sliding behavior of steels with different hardness

Abstract:

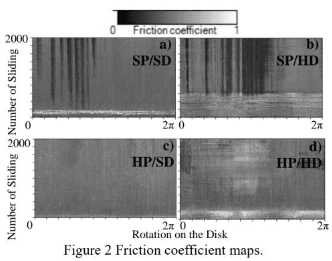

The adhesive wear mechanisms of medium carbon steel were analysed using spatiotemporal mapping analysis to know the influences of hardness of materials on the adhesion phenomena. The specimens were undergoing different heat treatment to condition their hardness. Dry sliding tests with different hardness combination of pin and disk specimens were conducted utilizing a pin-on-disk tribo-tester. As a result, the combinations including soft pin showed lower friction coefficient as comparing with those including hard pin. The difference between the combinations is supposed to be attributed to the characteristics of oxide layer formed by sliding.

Title: Effects of adsorbed water due to atmospheric humidity on ball-on-ball sliding contact

Abstract:

This research aimed to elucidate how adsorbed water influences friction and wear in a ball-onball sliding test. Since the force due to Laplace pressure, FLaplace at the contact interface is the function of relative humidity and surface roughness, they were selected as the manipulated variables in this study. To analyze the role of Laplace pressure, friction and wear at different contact positions were investigated. The empirical tribological results correlate with the theoretical equation of FLaplace developed. Hence, it can be concluded that Laplace pressure is predominant to both friction and wear at low relative humidity and low surface roughness.

Title: Fabrication of hard composite anodic films on aluminium alloy

Abstract:

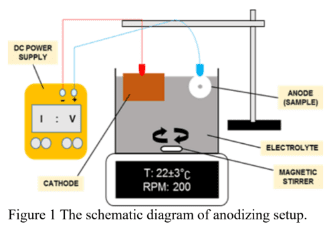

The anodic film containing particles has a good wear-resistance and self-lubricating properties which is beneficial to oil-free industrial machinery applications. In the present study, incorporation of graphene in the matrix of the coating will be used to reduce defects and improved tribological properties of aluminium alloy. The microstructure and cross section of the films was studied by scanning electron microscopy. Micro-hardness measurement and ball on disc wear tests was performed to evaluate the mechanical and tribological properties of the composites, respectively. The results show the that the composite anodic film has less micopores and better mechanical properties than the film without graphene. This composite anodic film could be the attractive advanced material for wide range of mechanical application.

Title: Long-term wear failure analysis of uhmwpe acetabular cup in total hip replacement

Abstract:

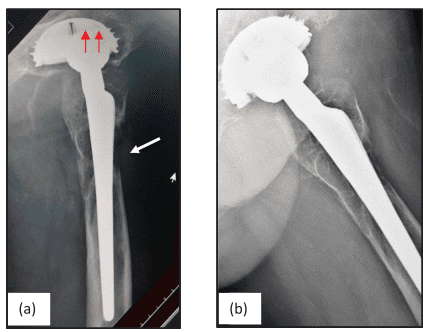

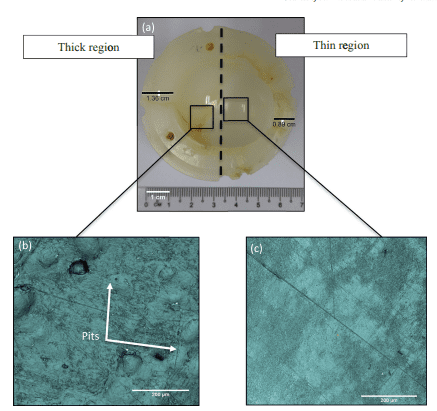

A revision of a metal-on-ultra high molecular weight (UHMWPE) bearing couple for total hip replacement was performed due to aseptic loosening after 23 years in-vivo. It is a major long-term failure identified from wear generation. This study includes performing failure analysis of retrieved polyethylene acetabular cup from Zimmer Trilogy® Acetabular system. The UHMWPE acetabular cup was retrieved from a 61 years old male patient with ability to walk but limited leg movement when he presented to hospital in early 2016 with complaint left thigh pain. It was 23 years after his primary total hip replacement procedure. Surface roughness and morphology condition were measured using 3D laser microscope and Scanning Electron Microscope (SEM) to evaluate and characterize the wear features on polyethylene acetabular cup surface. ATR-Fourier Transform Infra-Red (ATR-FTIR), differential scanning calorimetry (DSC) and gel permeation chromatography (GPC) were used to characterize the chemical composition of carbon-oxygen bonding, crystallinity percentage and molecular weight of the polymer liner that might changes the mechanical properties of polyethylene. Nano indentation is to measure hardness and elasticity modulus where the ratio of hardness to elastic modulus value can be reflected as the degradation of mechanical properties. A prominent difference of thickness between two regions resulted from acentric loading concentration was observed and wear rate were measured. The linear wear rate for thin side and thick side were 0.33 mm/year and 0.05 mm/year respectively. Molecular weight reduction of 57.5% and relatively low ratio of hardness to elastic modulus (3.59 × 10−3) were the indicator of major mechanical properties degradation happened on UHMWPE acetabular cup. This major degradation was contributed by oxidation and polishing wear feature accompanied with delamination, craters, ripple and cracks were the indication of extensive usage of UHMWPE from the suggested life span of acetabular cup application.

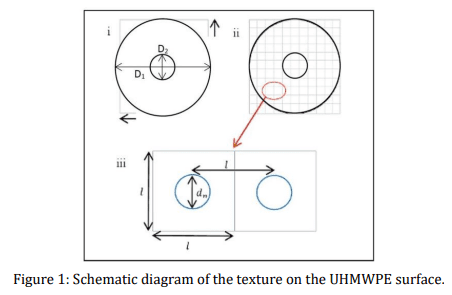

Title: Fabrication and wear characterization of dimple textured on the surface of UHMWPE

Abstract:

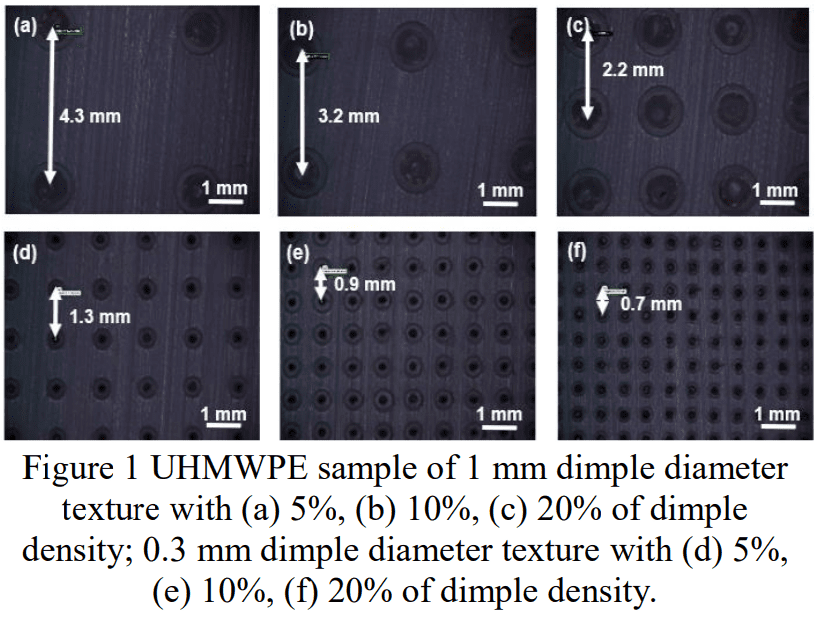

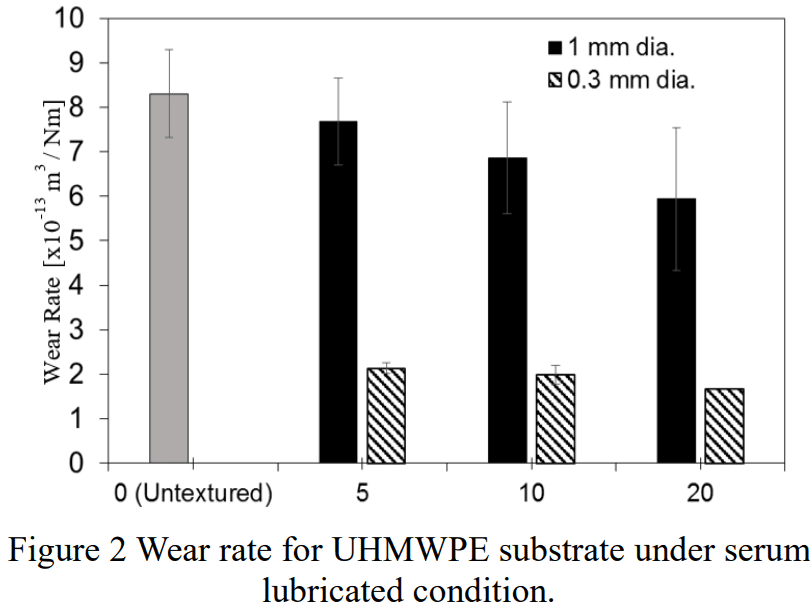

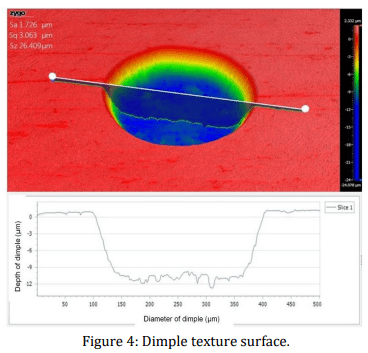

Wear are the major obstacle that limits the long-term using of ultra-high-molecular-weightpolyethylene (UHMWPE) in artificial joints. In this study, the micro-scale texture has been introduced to improve the wear properties of UHMWPE. The main objective of this study is to investigate the effect of surface dimple parameters on wear behaviour and mechanism of UHMWPE. Circular shaped micro-dimple with 40 µm in depth and different diameters (0.3 and 1 mm) as well as different area densities (5%, 10% and 20%) were machined by computer numerical control lathe machine. Wear performance of surface textured UHMWPE at different diameter and dimple densities under boundary serum lubricated conditions were studied. Results shows that by introduced texture on the surface does improved the wear resistance of UHWMPE where dimple with small diameter and high dimple density have low wear rate.

Title: Influences of surface roughness on the water adsorption on austenitic stainless steel

Abstract:

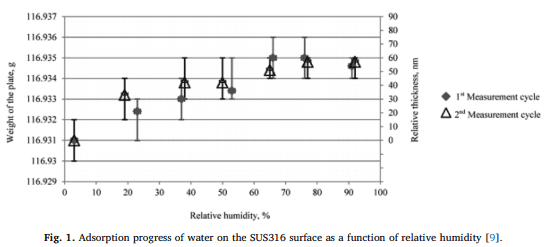

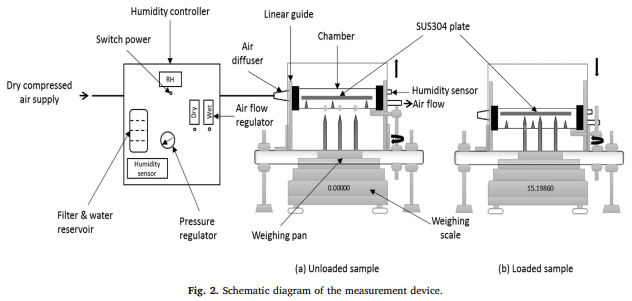

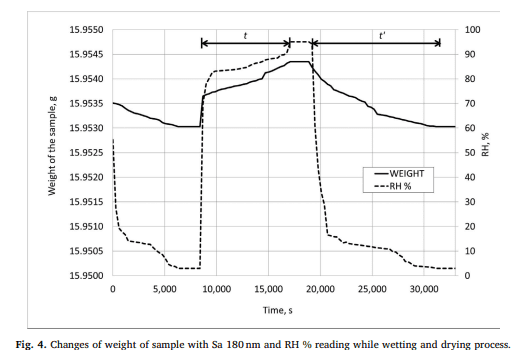

Presence of adsorbed water on the solid surface gives significant influences on the tribological phenomena. This study aims to elucidate how the difference in surface roughness of austenitic stainless-steel influences the amount of adsorbed water. Firstly, the necessary time for the adsorbed water to saturate on the surfaces with different roughness when relative humidity (RH) changed was determined by weighing method. Then, the saturated adsorbed water amount at different RH % was determined for the surfaces with different roughness. It was clarified that the rougher surfaces tend to require longer time for water adsorption to achieve the saturation level and adsorb more amount of water compared with smoother surfaces.

Title: Tribological behavior of hydrophilic and hydrophobic surfaces in atmosphere with different relative humidity

Abstract:

The significant influences of atmospheric humidity on tribological phenomena are widely recognized. Although the influencing mechanisms of the humidity have been studied for a long time, many of the previous explanations remain in the qualitative estimation of mechanisms particularly from chemical effects viewpoint. In order to elucidate how the adsorbed water on a surface influences tribological phenomena, the current authors conducted ball to ball scratch tests for austenitic stainless steel (JIS SUS304) and proposed the mechanisms from a physical/mechanical viewpoint. A singular phenomenon was found; a lateral force, which can be regarded as a friction resistance, at a downhill motion showed significantly higher value than that at an uphill motion. The phenomenon was hypothesized to be influenced by Laplace pressure effect at a meniscus formed due to adsorbed water on the surface. In this study, polytetrafluoroethylene (PTFE) as the hydrophobic material was tested in comparison with SUS304 to show that the adsorbed water layer causes the singular phenomenon. PTFE successfully prevented the singular phenomenon while SUS304 reproduced it. The equilibrium analysis of the ball showed that adsorbed water contributed to the increase of the coefficient of kinetic friction but not of negative normal force at the contact point of SUS304.

Title: Surface characterization of oxide films formed on aluminium alloy with the incorporation of graphite

Abstract:

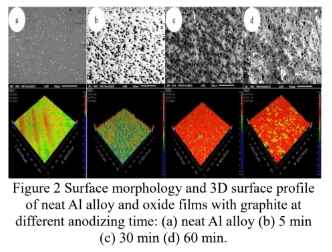

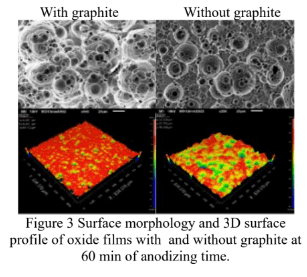

Hard anodizing represents useful surface treatment on aluminium alloy which provide good microhardness and wear resistance. Graphite is a good reinforcement in the oxide film due to its good mechanical, low friction and self-lubricating behavior. Thus, the aim of this research is to investigate the growth mechanism of oxide film surface containing graphite. The surface morphology and 3D images were observed on scanning electron microscopy and 3D profiler respectively. The film structure was examined by Raman spectroscopy. The result showed the surface porosity was reduced when comparing to the oxide film without graphite. Raman spectra of D and G peak proved the existence of graphite on the oxide film surface can be observed in early 5 min of anodizing process.

Title: Surface analysis of early retrieved polyethylene tibial inserts for both knees in total knee replacement

Abstract:

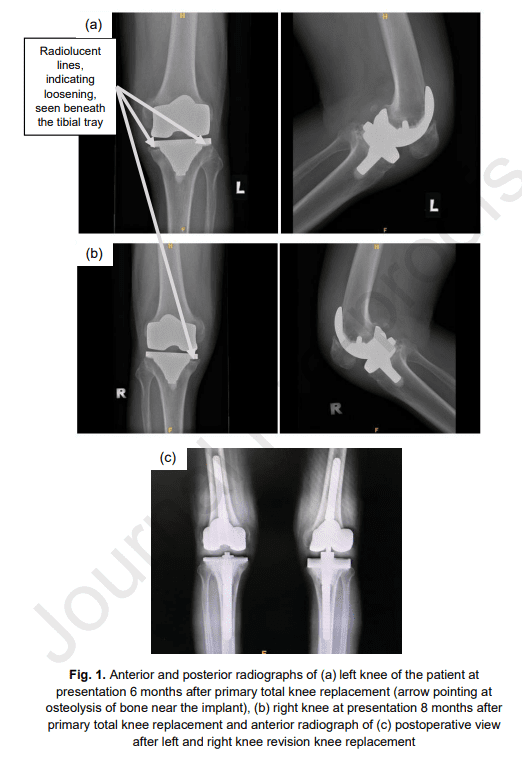

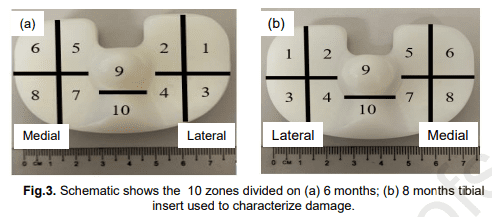

This study involves the failure analysis of a pair of ultra-high-molecular-weight-polyethylene (UHMWPE) knee tibial inserts from Scorpio® fixed-bearing total knee system by Stryker, which were retrieved from Total Knee Replacements (TKR) that was performed on 64 years old male patient with periprosthetic joint infection detected on both knees. Although the implants were removed due to infection, surface analysis was essential to be studied in order to analyse the surface damage mode of short-term implants. This study reports relevant damage mechanisms seen in early-retrieved UHMWPE tibial inserts (implanted for 6 and 8 months) and further analysis of chemical, physical and mechanical properties that possibly accompanied with failure. The surface characterization was done using a 3D laser microscope and Scanning Electron Microscope (SEM) to evaluate surface damage and dimensional change of both UHMWPE tibial inserts. Nano-indentation is used to measure the hardness and elasticity modulus of the tibial inserts. Attenuated Total Reflection-Fourier Transform Infra-Red (ATR-FTIR), Differential Scanning Calorimetry (DSC) and Gel Permeation Chromatography (GPC) were used to characterize the chemical and physical properties of the inserts. In present study, retrieved polyethylene inserts with short implantation duration was considered to have high-grade wear modes. The high incidence of micro pits (with the average depth of 27.5 μm for 6 months insert and 18 μm for 8 months insert) and scratches as the observed surface defects strengthen the role played by the particles upon defects generation for both tibial inserts. The average surface roughness of 6 and 8 months inserts were 1.6798 μm and 1.2376 μm, respectively. The rough surface (4.207 μm) of region 4 at the lateral compartment proves that the 6 months tibial insert suffered more damage due to loosening defect where the radiolucencies (the gap between bone and cement) were seen below medial and lateral aspects of the tibial tray. Our data demonstrated a strong association between the change of molecular weight and degradation of mechanical properties with wear for both inserts. The oxidation induced wear mechanism was observed on 6 months old insert due to the presence of delamination features with the evidence of in vivo oxidation from IR analysis.

Title: Carbon nanostructures grown from waste latex via chemical vapor deposition

Abstract:

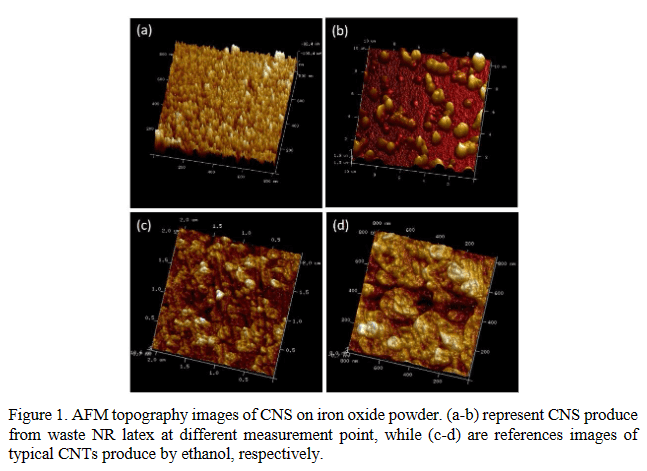

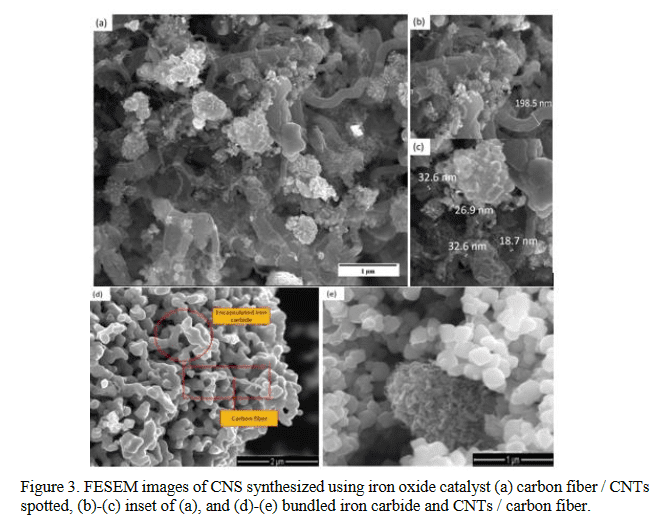

In this work, CNS were successfully synthesized using waste latex from natural rubber gloves as carbon source via chemical vapor deposition. The synthesized process has been done at reaction temperature of 700 C using iron oxide as catalyst. The CNS characterization were investigated by atomic force microscopy (AFM), field emission scanning electron microscopy (FESEM), transmission electron microscopy (TEM), Energy-dispersive X-ray spectroscopy (EDS) and Raman spectrum techniques. It was found that the obtained carbon material existed in the form of nanotubes, fibers and nanocapsules with diameter of 5-20 nm. The I G/I D value was found to be approximately 0.84, indicating CNS in the samples were not well crystalline and contain defects. HRTEM images and EDS results reveal non-uniform of large catalyst size and impurities of carbon source might lead to less population of grown CNTs. This study demonstrates that waste latex can be an alternative and inexpensive carbon source for CNS production and promotes green technology.

Title: Durability studies of real-time non-surfactant emulsion fuel supply system

Abstract:

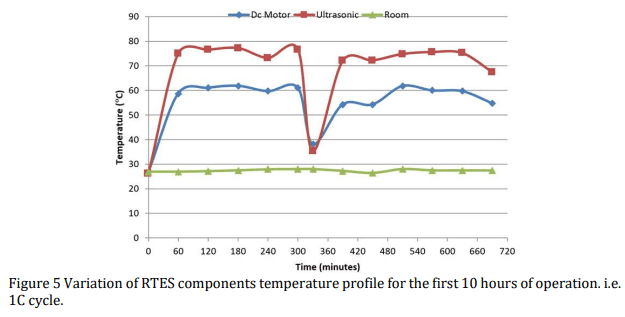

A device known as Real-Time Non-Surfactant Emulsion Fuel Supply System (RTES) was developed to eliminate the dependency of surfactant by rapidly supply the water in diesel (W/D) emulsion into the engine. The objective of this research is to run RTES under long term of operation. A new RTES was fabricated using ultrasonic transducer frequency is 50 kHz and speed of rotor is 1400 rpm. The amount of water injected into the system was constantly at 6.5 vol%. At the end of the test, temperature measurement and observation of RTES component were recorded and droplet size before and during the durability test was measured. It can be concluded that RTES can only withstand the long-term operation for total 26 hours. On the droplet size measurement, initial droplet size is 1.441µm, as the temperature of ultrasonic transducer increase, the droplet size also increases

Title: Effect of reaction temperature on the growth of carbon nanotubes from waste natural rubber glove

Abstract:

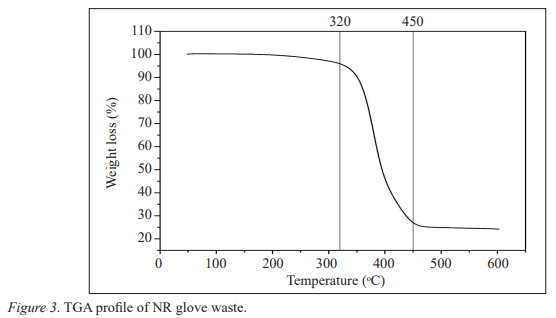

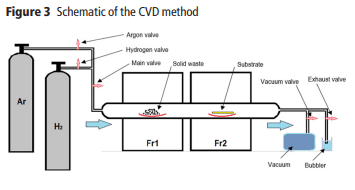

Natural rubber (NR) glove disposal is not environmentally appropriate and a range of approaches have been suggested to overcome the problem. Herein we indicate a simple method for producing high-value nanotubes from waste NR glove as a partial solution to the environmental problem. The laboratory-based waste NR glove was selected as a carbon precursor. Carbon nanotubes (CNTs) were synthesized using chemical vapor deposition (CVD) method comprising ferrocene over SiO2 substrate, which acted as a catalyst and surface for the carbon conversion process. The growth temperature was varied using 500, 600 and 700 C. The carbon precursor was analyzed using thermogravimetric analysis (TGA) to determine the optimum thermal decomposition of the waste. The CNTs collected after CVD process were analyzed using Raman spectroscopy, field emission scanning electron microscopy (FESEM), transmission electron microscopy (TEM). Optimization studies to determine the effect of temperature showed that the highest yield of CNTs was produced under a reaction temperature of 700 C (yield%= 5.47%, Raman ID/IG ratio= 0.82). The nanomaterials formed confirmed as CNTs and amorphous carbon under TEM images of the tubular structure of the products with a diameter range of 13–16 nm.

Title: Tribological performance of the graphene synthesized from fruit cover plastic waste and oil palm fiber using a CVD method

Abstract:

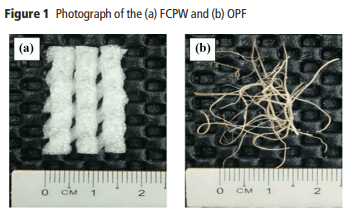

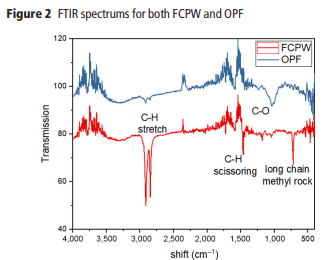

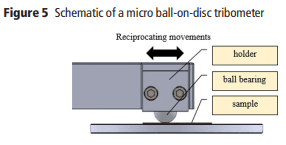

Natural rubber (NR) glove disposal is not environmentally appropriate and a range of approaches have been suggested to overcome the problem. Herein we indicate a simple method for producing high-value nanotubes from waste NR glove as a partial solution to the environmental problem. The laboratory-based waste NR glove was selected as a carbon precursor. Carbon nanotubes (CNTs) were synthesized using chemical vapor deposition (CVD) method comprising ferrocene over SiO2 substrate, which acted as a catalyst and surface for the carbon conversion process. The growth temperature was varied using 500, 600 and 700 C. The carbon precursor was analyzed using thermogravimetric analysis (TGA) to determine the optimum thermal decomposition of the waste. The CNTs collected after CVD process were analyzed using Raman spectroscopy, field emission scanning electron microscopy (FESEM), transmission electron microscopy (TEM). Optimization studies to determine the effect of temperature showed that the highest yield of CNTs was produced under a reaction temperature of 700 C (yield%= 5.47%, Raman ID/IG ratio= 0.82). The nanomaterials formed confirmed as CNTs and amorphous carbon under TEM images of the tubular structure of the products with a diameter range of 13–16 nm.

Title: Wear behavior of non-hydrogenated and hydrogenated DLC films under protein lubricated condition

Abstract:

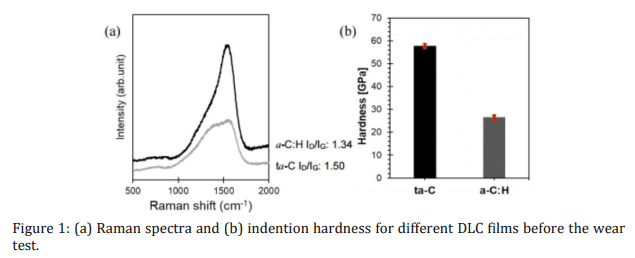

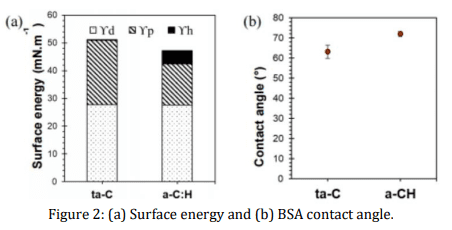

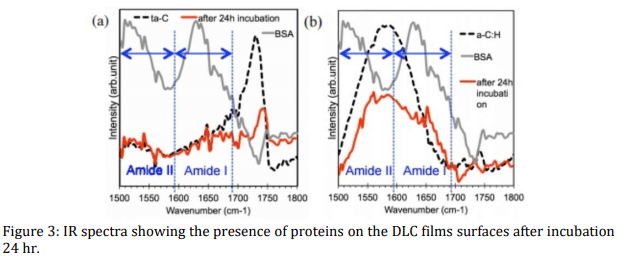

The differences in structure and wettability of diamond like carbon (DLC) films can influence the outcome of a wear test under protein lubricated condition. The aim of this study is to analyze the wear behavior of different structure of DLC films (ta-C and a-C:H) under bovine serum albumin as an attempt to simulate synovial fluid protein in artificial joints. The hardness, structure and surface wettability of films were investigated. Fourier transform infrared spectroscopy (FT-IR) was employed to investigate changes of protein conformation on the film surfaces after incubation for 24 h at 37°C. The wear behavior of DLC films and its counterpart, ultra-height molecular weight polyethylene (PE) were assessed by reciprocating tribo tester. There is a correlation between surface wettability, protein absorption and wear behavior, and in this study, it has been found that the surface of a hydrophobic a-C:H film tends to bind more protein due to the contribution of hydrogen bonds. As a result, the wear rate of PE against a-C:H film is found to be low due to adsorbed protein acts as a lubricant film and protects the surface from wear

Title: Wear Mechanism of Treated Oil Palm Empty Fruit Bunch Fibre Reinforced Polyoxymethylene Composite

Abstract:

The present study aims to investigate the potential improvement in the wear resistance of polyoxymethylene (POM) based composite using oil palm empty fruit bunch (OPEFB) fibre as reinforcement. This is to provide a prospective candidate of tribo-materials for low friction application such as bearing composite. Initially, the OPEFB fibre were treated with sodium hydroxide solution for 1 h at 2 wt% concentration to improve the fibre-matrix adhesion. Untreated and treated OPEFB fibre were incorporated into POM matrix to develop composite using a compression moulding technique under different fibre loading (10, 20 and 30 wt%). Subsequently, its wear mechanism was observed using a pin-on-disc machine at applied load 30 N and sliding speed 100 rpm under dry contact condition. Scanning electron microscope (SEM) was used to analyze the worn surface morphology. The results revealed that massive damages were observed on the untreated composite compared to treated composite. The wear mechanism of the OPEFB/POM composite was predominated by micro-cracks, deep groove and delamination.

Title: Effect of CNT on microstructural properties of Zn2SiO4/CNT composite via dry powder processing

Abstract:

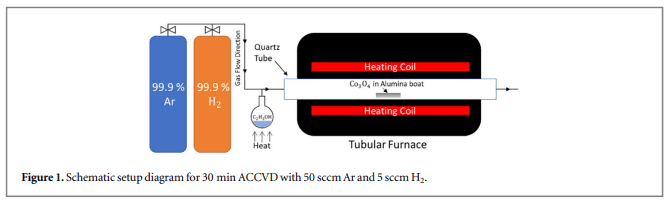

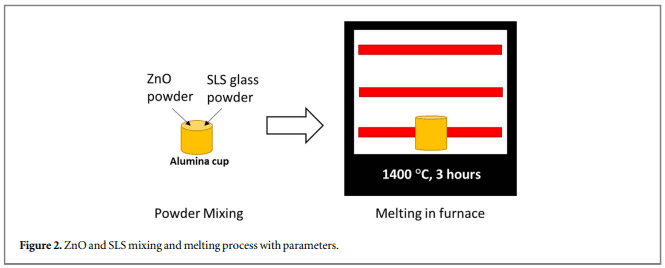

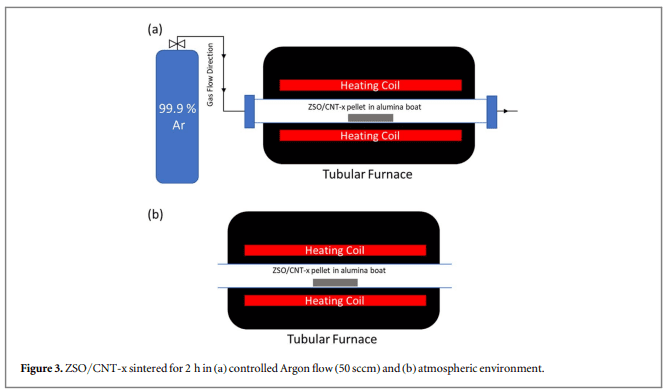

This work focused on the influence of carbon nanotubes (CNT) to the microstructural properties of Zn2SiO4/CNT (ZSO/CNT) composite. CNT was synthesized via alcohol catalytic chemical vapor deposition (ACCVD) using cobalt oxide as catalyst and ethanol as carbon source. Zinc silicate (ZSO) glass was prepared from quenching the melted commercial waste glass bottle with zinc oxide powder. ZSO/CNT-x composites with various CNT concentration (0, 1, 2 and 3 wt%) was prepared through introducing CNT into ZSO glass via dry processing technique followed by sintering process in Argon gas (Ar) environment and atmospheric (atm) environment, respectively. FESEM, XRD and EDS were employed to determine the surface morphology, phase composition and elemental distribution of sintered sample. Crystallite trigonal willemite (Zn2SiO4) phase was observed from argon sintered sample and the crystallite size of willemite phase in ZSO/CNT-3/Ar showed the most reduced lattice strain of 22.85% compared to ZSO/CNT-0/Ar. In contrast, semi-crystalline phase exhibited in atmospheric sintered sample resulted in high lattice strain. It is concluded that dry powder processing and inert gas thermal treatment can be an effective technique in fabricating strain-reduced ceramics/CNT composite without alternating the domain phase. Least internal strain in crystal lattice have potential on enhancing the luminescence properties of phosphor material and lattice thermal conductivity of thermoelectric material.

Title: Surface analysis of retrieved bilateral UHMWPE tibial inserts under varus malalignment condition

Abstract:

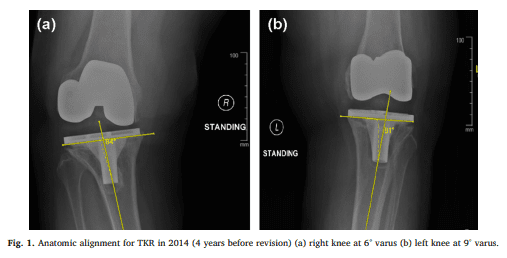

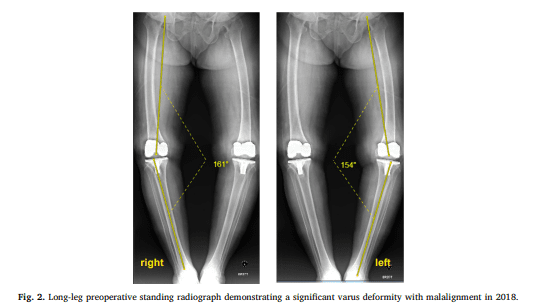

Failure analysis on a retrieved ultra-high molecular weight (UHMWPE) knee tibial inserts of bilateral total knee replacement (TKR) was performed due to aseptic loosening detected after 16 years (left) and 12 years (right) in vivo services. Despite long implantation time, the effect of varus malalignment present on a 71 years old female patient (body mass index, 35.1) with a non-active lifestyle will be considered as a factor towards the TKR failure. We, therefore, determined whether implant malalignment was associated with increased surface damages in both retrieved tibial inserts. Surface damage morphology was assessed using a 3D laser microscope and Scanning Electron Microscope (SEM). ATR-Fourier Transform Infra-Red (ATR-FTIR), Differential Scanning Calorimetry (DSC) and Gel-Permeation Chromatography (GPC) were used to measure changes of chemical and physical properties of retrieved inserts. Results show left-16 years insert possesses more severe wear degradation (crater and cracks) compare to wear on right-12 years insert (delamination, multidirectional scratches, and ripple). The surface roughness on the medial compartment seems to be higher than the lateral side for both inserts which can be affected by uneven load distribution contribute by the varus deformity. Higher crystallinity of left-16 years insert (66.99%) compare to right-12 years insert (56.52%) were an indicator of major mechanical changes happen on left insert which was contributed by oxidation with respect to implantation time of both inserts. Our findings revealed that in vivo oxidation is a main contributing factor to the failure of implants, but not varus malalignment. The material properties in the oxidized layer are significantly altered, including a very substantial reduction in molecular weight displayed by both inserts.

Title: Tribological studies on ultra-high molecular weight polyethylene with palm kernel shell in dry condition

Abstract:

The tribological performance of the Ultra high molecular weight polyethylene (UHMWPE) with different compositions (0, 5, 10, and 15 wt.%) of palm kernel shell (PKS) composite was investigated by using pin-on-disc tribometer at dry sliding condition. All specimens were fabricated into 74 mm diameter disc of 4 mm height with different compositions (0, 5, 10, and 15 wt.%) of PKS by undergo hot press process. The outcomes demonstrated that the coefficient of friction (COF) and wear rate were steadily decreased as the composition of PKS is enhanced. The pure UHWMPE have the highest COF and wear rate of 0.086 and 6.24 x 10-6 mm3/N. mm while the UHMWPE reinforced 15 wt.% PKS have lowest COF and wear rate of 0.063 and 5.13 x 10-6 mm3/N. mm. Low COF and low wear rate for higher wt.% of PKS is due to high wt.% transferred layer of carbon elements and surface hardened with reinforcement of PKS.

Title: Strengthening of the mechanical and tribological properties of composite oxide film formed on aluminum alloy with the addition of graphite

Abstract:

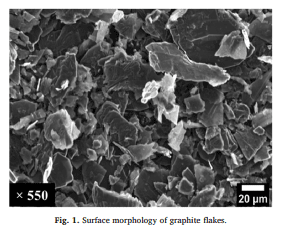

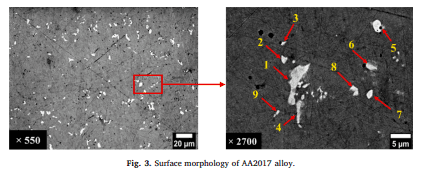

Composite oxide films containing graphite were fabricated using the anodizing technique on AA2017- T4 aluminum alloy in diluted sulfuric acid (20 wt%). This study aims to evaluate the effect of graphite on the film growth and investigate its impact on the self-lubricating ability and durability of the composite films. The growth mechanism was determined by manipulating the anodizing time while the mechanical and tribological properties of the films were studied with different graphite content. The surface morphology, topography, and chemical compositions were examined with scanning electron microscopy (SEM), 3D optical profiler, and energy- dispersive spectroscopy (EDS), respectively. The microhardness was characterized at the surface and cross-section of the films by Vickers microhardness tester. The structure of the oxide films and graphite were studied by X-ray diffractometer (XRD) and Raman spectroscopy. The tribological characterization was investigated by using a ball-on-disk sliding test in dry condition. The growth of the film was initiated by the formation of the non-porous barrier layer at 5–10 min. The pores started to grow at 20 min and caused the break of the barrier layer. For this process, the complete development of porous composite oxide film can be achieved at 60 min with the pore dimension (width: 23.74 ± 8.91 μm; depth: 27.9 ± 9.09 μm). The thickness of 1 g/L oxide film at 60 min was about 32.45 ± 4.92 μm, approximately. The incorporation of graphite reduces the surface porosity of oxide films and improves the mechanical and tribological properties significantly. The service life of the composite oxide film is affected by the hardness and graphite-self-lubricated layer.

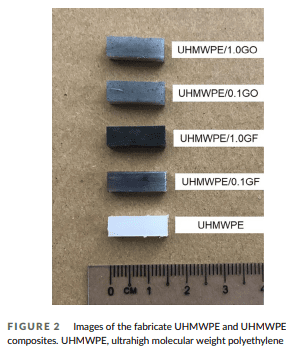

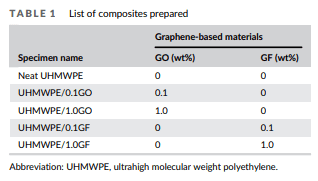

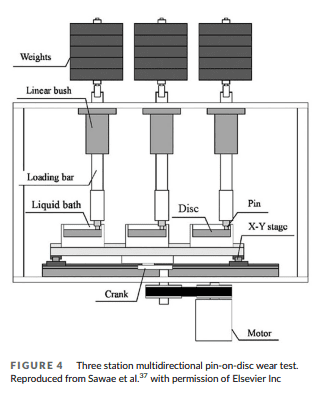

Title: The relations between wear behavior and basic material properties of graphene‐based materials reinforced ultrahigh molecular weight polyethylene

Abstract:

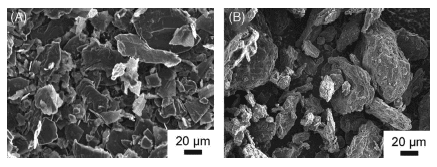

This article aims to investigate the influence of reinforcing graphene oxide (GO) and graphite flakes (GF) fillers into ultrahigh molecular weight polyethylene (UHMWPE) for orthopedic application. These fillers were expected to physically bond to UHMWPE, thus can enhance the subsurface strength, improving the wear behavior of the composites. UHMWPE/GO and UHMWPE/GF composites were prepared at 0.1 and 1.0 wt% by melt-blending, followed by a compression molding technique. A multidirectional pin-on-disc wear test was performed to simulate the kinematic of hip application. Whilst getting exposed in the artificial in-vivo lubricant bath (30 v/v% diluted bovine serum). Following this, the wear mechanism fostered by each filler (GO and GF) was determined by wear features obtained from the optical microscope and scanning electron microscope (SEM). The crystallinity degree and crystal defect were assessed using x-ray diffraction (XRD). The mechanical properties of fabricated composites were evaluated by using a universal testing machine and Vickers microhardness. We found that UHMWPE/GO has the lowest specific wear rate due to the improved subsurface strength, as the reduction of a weak adhesive point was observed on the worn surface. Meanwhile, higher GF content (1 wt%) in UHMWPE displayed a lower specific wear rate than neat UHMWPE after completing the 10 km sliding distance attributed to the filler resurfaced, responsible for providing a strong resistance of the shear stress applied upon sliding with the metal counterface. Interestingly, the hardness and tensile strength for both UHMWPE/GO and UHMWPE/GF increased, although the crystallinity percentage was declining compared to neat UHMWPE.

Title: The effect of humidity on friction behavior of hydrogenated HIPIMS WC: H coatings

Abstract:

The study of the effect of humidity on friction behavior in HiPIMS (High Power Impulse Magnetron Sputtering) W-C:H coating/steel ball system confirmed the formation of transfer layer adhered to the ball and consisting of hydrogenated carbon, ferritungstate and small amounts of tungsten (sub)oxides and iron oxides. The corresponding mechano(tribo)chemical reactions driven by flash temperature in the sliding asperities involved oxidation, water vapor dissociation and carbon hydrogenation. Such composition agreed with the results of modelling based on the minimization of free Gibbs energy in the mutually interacting thermochemical reactions. The applicability of modelling to friction was attributed to fast reactions among microscopic asperities eliminating kinetical factors. In inert atmospheres, oxidation and hydrogenation were suppressed and friction seemed to be controlled by the amount of additional carbon.

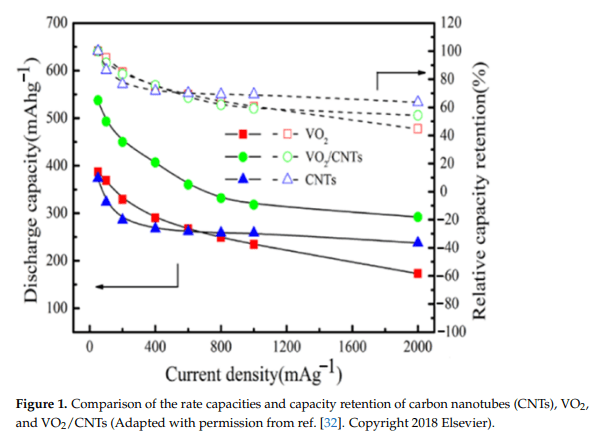

Title: Carbon-Based Materials Reinforced Ultrahigh Molecular Weight Polyethylene and Biocomposites

Abstract:

The chapter represents a comprehensive review of inorganic particles reinforced the ultra-high molecular weight polyethylene (UHMWPE) to promotes better operational properties as compared to pure UHMWPE for orthopaedic applications. A strong interfacial adhesion between UHMWPE matrix-based particle filler is believed to be the major factor influencing the UHMWPE based composite material’s properties outcome. Hence, graphene oxide and graphite were reviewed as the potential reinforcement particles due to its special additional properties; biocompatible, high thermal conductivity, hydrophilic behavior and could act as a nucleating agent, which rarely found in other type of materials in current market. UHMWPE based carbon-based reinforced composite with optimum processing parameters and wt% shows improved mechanical properties. UHMWPE reinforced cabon-based particle exhibited remarkable mechanical properties which have the potential to be the alternative materials for joint orthopaedic applications.

Title: Fabrication and tribological characterization of aluminium alloy by using photochemical machining

Abstract:

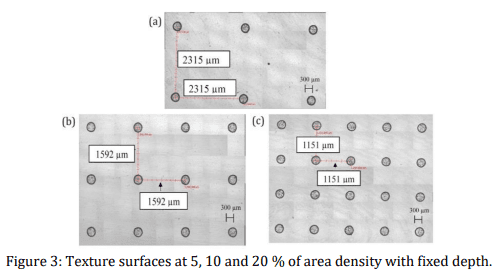

Photochemical texturing (PCT) is a widely used method to modify physical topography of the surface nearly all type of materials. However, the usage of this method is the most commonly used in microelectronic mechanical systems (MEMS) industries. While there have been few reported studies on the use of PCT technique for metal surfaces and there has been very limited work on the tribological characteristics from such surfaces. Therefore, the objective of the present work was to gain a better understanding on the wear and friction behaviour of textured aluminium alloy, AA2017-T4 by considering their geometrical texture characteristics. In this study, AA2017-T4 disks have been texturized into circular dimples with different area density (0 to 20%) and depth (5 to 15µm). Ball on disc tests were performed under dry condition. The worn surface of AA2017-T4 disks was analyzed to understand the wear mechanism and durability of the textured surface during testing. The results indicate that a higher density of circular dimples (20%) had less wear and a lower coefficient of friction compared to non-textured disk. The results suggest that the tribology performance is only dependent on the surface area density but does not influence by depth characteristics

Title: Waste NR Latex Based-Precursors as Carbon Source for CNTs Eco-Fabrications

Abstract:

In this work, the potential of utilizing a waste latex-based precursor (ie, natural rubber glove (NRG)) as a carbon source for carbon nanotube (CNT) fabrication via chemical vapor deposition has been demonstrated. Gas chromatography-mass spectroscopy (GC-MS) analysis reveals that the separation of the lightweight hydrocarbon chain from the heavier long chain differs in hydrocarbon contents in the NRG fraction (NRG-L). Both solid NRG (NRG-S) and NRG-L samples contain> 63% carbon,< 0.6% sulfur and< 0.08% nitrogen content, respectively, as per carbon-nitrogensulfur (CNS) analysis. Growth of CNTs on the samples was confirmed by Raman spectra, SEM and TEM images, whereby it was shown that NRG-S is better than NRG-L in terms of synthesized CNTs yield percentage with similar quality. The optimum vaporization and reaction temperatures were 350 and 800◦ C, respectively, considering the balance of good yield percentage (26.7%) and quality of CNTs (ID/IG= 0.84±0.08, diameter≈ 122 nm) produced. Thus, utilization of waste NRG as a candidate for carbon feedstock to produce value-added CNTs products could be a significant approach for eco-technology.

Title: Effect of Protein Interactions on the UHMWPE Composites After the Multidirectional Wear Test

Abstract:

Recent studies have found a rapid increase of ultrahigh molecular weight polyethylene (UHMWPE) wear in the presence of proteins from the synovial fluid. This is due to the high hydrophobicity surface of UHMWPE which allows the proteins to get interacted and adsorbed to the UHMWPE surface. Moreover, since UHMWPE has low thermal conductivity, the heat elevated produced from the articulating contact surfaces would be slowly dissipated and protein structure becoming denatured. The denatured proteins were claimed could increase the adhesive wear response. Thus, the main objective of this study is to evaluate the influence of the graphene oxide (GO) and graphite flake (GF) on the UHMWPE’s heat dissipation and wettability characteristics in regards to reducing the protein denaturation effect on the surface. The surface properties were characterized by using surface energy evaluation, zeta potential, and Fourier Transform Infra-red (FTIR). Following that, wear properties of each UHMWPE composite were evaluated by using a multidirectional pin-on-disc wear test under a lubricated condition. The worn surface of each pin sample was evaluated, and the dominating factors of wear properties were determined. In addition to that, the effect of protein absorption on the UHMWPE composites was also evaluated in this study. The results show both fillers (GO and GF) had no effect in altering the UHMWPE composites’ physicochemical properties. The improvement of UHMWPE composite’s wear properties was discovered to be primarily dominated by the existence of GO filler (1.0 wt%) near the sliding surface has improved the subsurface strength of the material and heat dissipation effect which reduces the denaturation of the proteins.

Title: Recent developments in carbon nanotubes-reinforced ceramic matrix composites: A review on dispersion and densification techniques

Abstract:

Ceramic matrix composites (CMCs) are well-established composites applied on commercial, laboratory, and even industrial scales, including pottery for decoration, glass–ceramics-based light-emitting diodes (LEDs), commercial cooking utensils, high-temperature laboratory instruments, industrial catalytic reactors, and engine turbine blades. Despite the extensive applications of CMCs, researchers had to deal with their brittleness, low electrical conductivity, and low thermal properties. The use of carbon nanotubes (CNTs) as reinforcement is an effective and efficient method to tailor the ceramic structure at the nanoscale, which provides considerable practicability in the fabrication of highly functional CMC materials. This article provides a comprehensive review of CNTs-reinforced CMC materials (CNTs-CMCs). We critically examined the notable challenges during the synthesis of CNTs-CMCs. Five CNT dispersion processes were elucidated with a comparative study of the established research for the homogeneity distribution in the CMCs and the enhanced properties. We also discussed the effect of densification techniques on the properties of CNTs-CMCs. Additionally, we synopsized the outstanding microstructural and functional properties of CNTs in the CNTs-CMCs, namely stimulated ceramic crystallization, high thermal conductivity, bandgap reduction, and improved mechanical toughness. We also addressed the fundamental insights for the future technological maturation and advancement of CNTs-CMCs.

Title: Fabrication and tribological characterization of aluminium alloy by using photochemical machining

Abstract:

Photochemical texturing (PCT) is a widely used method to modify physical topography of the surface nearly all type of materials. However, the usage of this method is the most commonly used in microelectronic mechanical systems (MEMS) industries. While there have been few reported studies on the use of PCT technique for metal surfaces and there has been very limited work on the tribological characteristics from such surfaces. Therefore, the objective of the present work was to gain a better understanding on the wear and friction behaviour of textured aluminium alloy, AA2017-T4 by considering their geometrical texture characteristics. In this study, AA2017-T4 disks have been texturized into circular dimples with different area density (0 to 20%) and depth (5 to 15µm). Ball on disc tests were performed under dry condition. The worn surface of AA2017-T4 disks was analyzed to understand the wear mechanism and durability of the textured surface during testing. The results indicate that a higher density of circular dimples (20%) had less wear and a lower coefficient of friction compared to non-textured disk. The results suggest that the tribology performance is only dependent on the surface area density but does not influence by depth characteristics